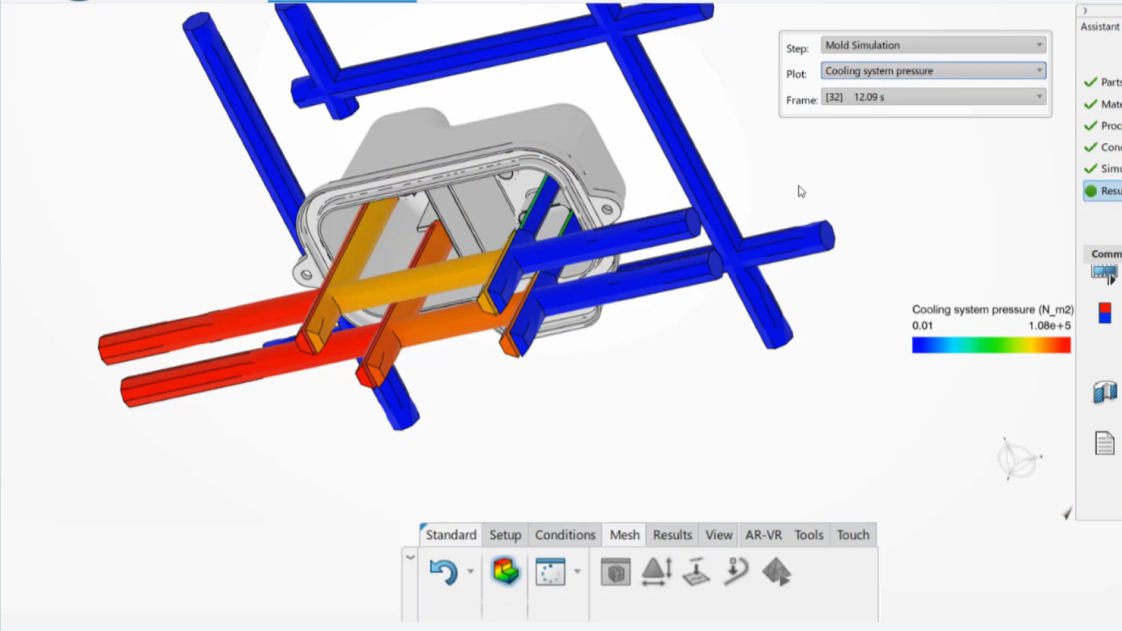

SOLIDWORKS Plastics Injection Molding Simulation

SOLIDWORKS Plastics is a specialized simulation tool that helps designers, mold makers, and manufacturing engineers predict how molten plastic flows during the injection molding process. By simulating the filling, packing, cooling, and warpage phases, SOLIDWORKS Plastics empowers users to identify defects early, reduce manufacturing costs, and ensure high-quality molded parts—before cutting any steel.

The simulation engine calculates how plastic flows through a mold cavity using finite element analysis (FEA) and advanced flow algorithms. With intuitive tools and a native SOLIDWORKS interface, engineers can optimize part designs, gate locations, runner systems, and cooling layouts while maintaining full associativity with their CAD models.

SOLIDWORKS Plastics Standard

SOLIDWORKS Plastics Standard gets you started with essential plastics simulation, with features like:

Plastic Flow Simulation

Automatic Gate Location

Fill Time & Pressure Prediction

Visualization of Weld Lines and Air Traps

Ideal for parts designers needing basic mold flow simulation.

SOLIDWORKS Plastics Professional

Professional builds on top of Standard, offering more advanced simulation abilities like:

Multi-cavity & Family Mold Analysis

Runner Balancing & Gate Optimization

Cycle Time Estimation

Mold Cooling Time

Great for mold designers, needing additional capabilities

SOLIDWORKS Plastics Premium

Finally, Premium delivers full insight into mold performance with features like:

Cooling Line Analysis

Warpage Prediction

Mold Temperature Imbalance Detection

Full Mold Performance Validation

For those who need advanced plastic part validation.